Engineering excellence

UK & European Manufacturing & Global Distribution Of Ball & Roller Bearings, Mechanical Power Transmission parts, Motion Transfer Linkages And More.

BTL-UK manufactures high quality ball & roller bearings, mechanical power transmission products and motion transfer linkages. We are proud to be the licence holder of the prestigious DUNLOP brand. This makes our products instantly recognisable. These products are accepted throughout the World by leading original equipment manufacturers in the agricultural, construction, industrial, motorsport and medical industries.

In addition, BTL-UK also manufacturers V-belts, Timing belts (synchronous) and Micro-V-belts carrying the trademark of MEDWAY. Representing our ‘AGRI’ product range, also produced to high dimensional tolerances. They have been designed for use in the harshest of environmental conditions.

The ‘Go-To’ brand

BTL-UK products are accepted as the ‘go-to’ brand when replacement products are required within the maintenance, repair, and overhaul sectors.

With three manufacturing sites within the UK, BTL-UK also works closely with other leading manufacturing partners throughout Europe and Asia. This makes BTL-UK ideally placed to meet the requirements and expectations of its customers on a global scale.

A comprehensive network of MRO & replacement distributors throughout Europe and the rest of the world ensures products are readily available, and are always delivered quickly and efficiently.

There are 4.2m private companies in the UK. Only 1% or 45,000 of these companies are considered ‘high growth’. We are delighted to announce BTL-UK has been listed in the 2022 FEBE Growth 100 list.

DISTRIBUTOR WEB SHOP

BTL-UK LTD is one of Europe’s leading manufacturers and international distributors of Bearings, Transmissions and Linkages. Thousands of part numbers are available in just one click!

BECOME A DISTRIBUTOR

There are huge advantages and excellent revenue earning potential. Call us now or complete the form to give us additional information about your organisation

Brands

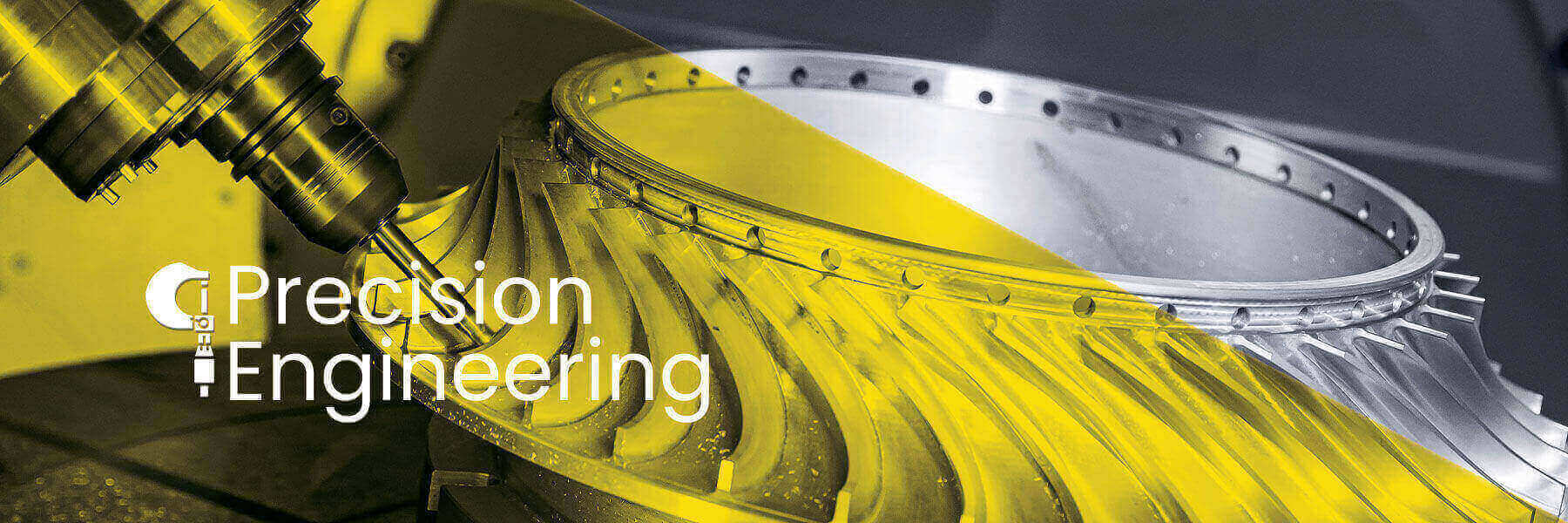

BTL PRECISION

BTL Precision is a subsidiary of BTL-UK producing high quality sub-contract high precision engineered components to individual customer requirements.

Capabilities include CNC, sliding head and auto lathes and milling machines and gear cutting of timing pulleys, sprockets and gears used in industries including aerospace, automotive, agricultural, motorsport, safety, transport, and telecoms, working together with customers to overcome design and application difficulties.

DUNLOP

The Dunlop brand is an instantly recognised symbol of reliability around the world, with a reputation for high-quality products and service.

At BTL-UK we have a passion for performance that is built into our company DNA, we are continuously pushing boundaries and developing new, exciting technologies and products. We are proud to be part of this unique heritage as the manufacturer of this prestigious brand.

MEDWAY

Medway represents our ‘AGRI’ product range which offers Vee belts, Timing belts and Micro-V belts. Produced to tight dimension tolerances, they have been designed for use in the harshest of environments.

Available in both metric and imperial dimensions, gives a wide range of product options and choice and having good resistance to mineral oils and temperature ranges whilst withstanding high shock loads they are ideal for agricultural applications.

MSK MEDICAL

MSK equals high quality and high performing PPE equipment. General purpose civil face protection for the public and company employees, can be obtained cost efficiently whilst more demanding applications FFP2 respirator face masks are fully certified to BS EN 149:2001.

CE marked to meet all UK and European regulations. When used in conjunction with MSK face shields this gives care workers maximum reassurance and protection.

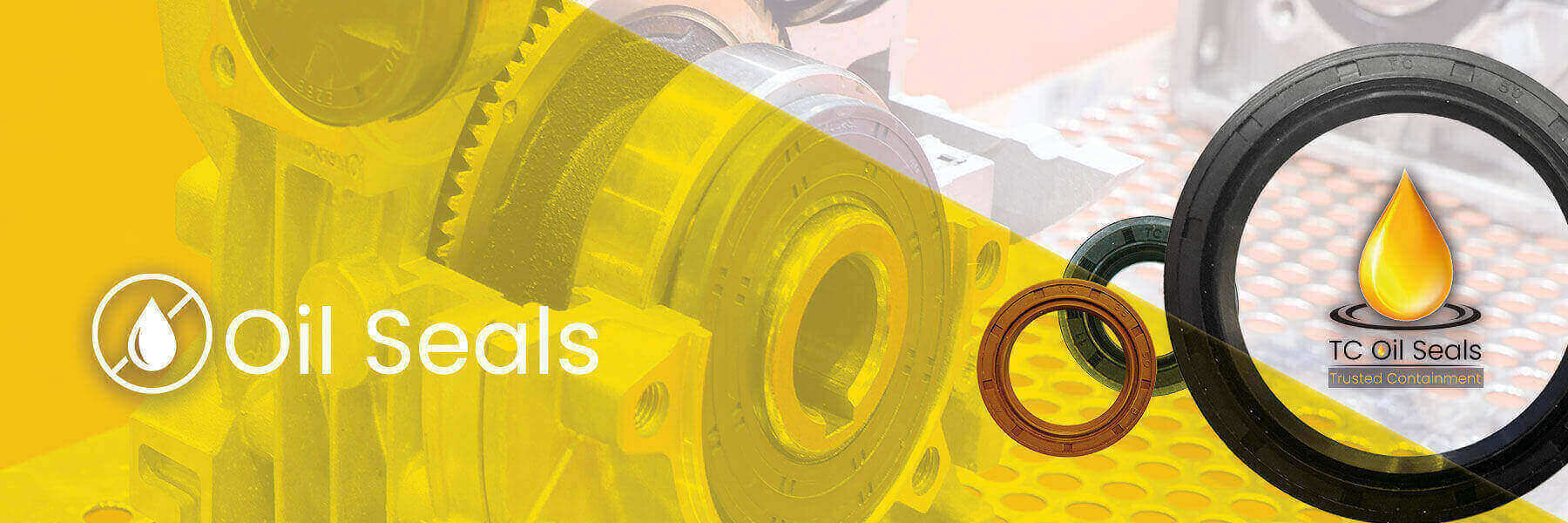

TC OIL SEALS

Oil Seals also called rotary shaft seals are widely used to prevent the leakage of a medium (such as oil and grease) along a rotating shaft.

It is a mechanical component used to seal in the lubricant, oil and grease being the most common liquid substances found in any power transmission system such as an engine, gear box or electric motor, but also seals all general liquid substances.